Understanding the Shewhart Cycle

The Shewhart Cycle: The Foundation of Continuous Improvement

In the world of quality control and management, the Shewhart Cycle, also known as the PDCA Cycle, stands as a seminal concept. Originating from Walter Shewhart, this methodology emphasizes a relentless pursuit of improvement through a systematic approach. As you navigate strategic planning at a corporate level, understanding the nuances of this cycle could unlock significant potential for your organization. The Shewhart Cycle, often synonymous with the Deming Cycle, comprises four distinct phases: Plan, Do, Check, and Act. These phases encapsulate a process aimed at continuous improvement. The ultimate goal is to foster a culture where change is not feared but embraced as a precursor to innovation and growth.- Plan: Here, the initial groundwork is laid. This phase involves identifying opportunities for change, developing hypotheses, and formulating a strategic plan. It's essential to leverage quality management practices and set clear objectives to guide subsequent steps.

- Do: During this phase, the strategies designed in the planning stage are implemented on a small scale to test their efficacy. By executing the plan at this stage, you allow your team to generate tangible insights into potential improvements.

- Check: This is where analysis takes the stage. The focus is to evaluate outcomes against predetermined metrics. Utilizing aspects of project management, organizations can identify discrepancies between expected and actual results, which then inform future planning.

- Act: Concluding the cycle, the Act phase is about institutionalizing successful strategies or returning to earlier phases when objectives are not met. This embodies the principle of continuous learning and adapting.

Integrating the Cycle into Strategic Planning

Embedding the PDCA Cycle into Strategic Frameworks

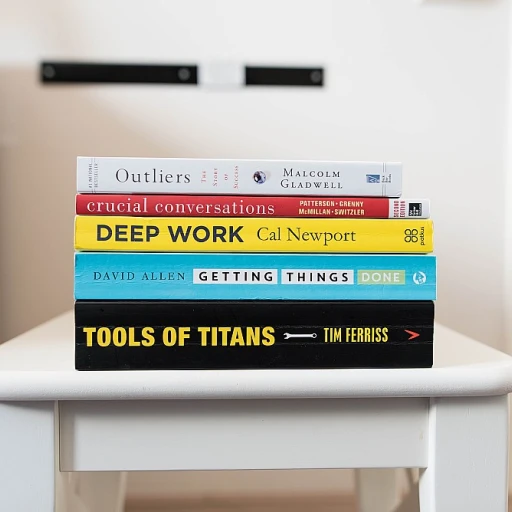

Incorporating the Shewhart Cycle, also known as the PDCA cycle, into strategic planning can serve as a catalyst for ongoing organizational development and improvement. This approach not only enhances quality management but also strengthens the overall project management process. The PDCA, which stands for Plan-Do-Check-Act, is a pragmatic framework that iteratively refines processes and drives continuous improvement. It begins with the 'Plan' phase, where you identify problems, set objectives, and develop an actionable plan. This step is crucial as it sets the foundation for subsequent actions. Following the planning stage, the 'Do' phase involves implementing the plan on a small scale to test its effectiveness. After implementation, the 'Check' phase is where evaluative methods are employed to monitor progress and gauge the success of the initiatives. Here, reviewing data and outcomes ensures that objectives align with the strategic goals. The cycle culminates in the 'Act' phase, where insights gained from the 'Check' phase inform adjustments and refinements, ultimately embedding improvements into the business strategy. One of the critical advantages of integrating this methodology into strategic frameworks is its systematic approach to change management. By emphasizing quality control and problem solving, the PDCA cycle enables businesses to adapt smoothly to market dynamics. Moreover, the continuous nature of this strategic device allows for ongoing learning and adaptation, fostering an environment that embraces innovation and resilience. This proactive stance ensures that any adjustments are made swiftly, thereby maintaining competitive advantage. To gain deeper insights into mastering corporate strategy with the PDCA cycle, you might find valuable perspectives in essential resources on strategic planning. Essential Reads for Mastering Corporate Strategy offers further reading on embedding quality frameworks into strategic planning efficiently. Integrating the Shewhart PDCA cycle into your strategic planning processes not only facilitates robust management but also ensures that your organization remains agile and prepared for future challenges.Enhancing Decision-Making with PDCA

Empowering Strategic Decisions with PDCA

Integrating the Shewhart Cycle into your organization's strategic framework can revolutionize the decision-making process. The cycle, consisting of Plan, Do, Check, and Act (PDCA), offers a systematic approach that ensures decisions are thoughtful and calculated. Applying this cycle in strategic planning aids in breaking down complex decisions into manageable phases. Here’s how each phase can be leveraged:- Plan: Begin by identifying objectives and gathering data. This step involves analyzing potential changes or improvements and setting the groundwork for achieving desired results.

- Do: Implement the decisions on a small scale to test their viability. This phase is critical for minimizing risks, allowing teams to work through initial hitches.

- Check: Evaluate the outcomes of the implementation phase by comparing the achieved results against the initial objectives. This quality control step is crucial for identifying areas of improvement.

- Act: Implement full-scale changes based on the successful strategies identified during the Do and Check phases. Continuous refinement is key, fostering a culture of continuous improvement.

Case Studies: Success Stories

Real-World Applications of the Shewhart Cycle

Examining real-world applications unveils the potential of the Shewhart Cycle, or PDCA cycle, to drive strategic excellence. Businesses that have adeptly integrated this cycle into their operations showcase a commitment to continuous improvement and quality management.

In one instance, a renowned manufacturing company embarked on a journey to enhance their product quality. They commenced with the plan phase, identifying gaps in their processes through rigorous analysis. The subsequent do phase involved the implementation of changes on a small scale, allowing for meticulous documentation and assessment. This step was pivotal in understanding the impact of each change within the safe confines of a controlled environment.

The check phase illuminated areas that required further refinement, enabling the management to make data-driven decisions. Emphasizing a strong feedback loop, the act phase was a testament to the company's agility and commitment to excellence. The strategic cycle was repeated, ingraining a culture of quality control and continuous improvement.

From the tech industry, an innovative software company leveraged the Shewhart Cycle to refine their project management methodologies. Each project began with a cycle plan emphasizing stakeholder collaboration and agile adaptations. The do, check, and act phases transformed into a seamless process that not only enhanced quality but also boosted team learning, leading to exceptional customer satisfaction.

These success stories underscore the versatility of the Shewhart-PDCA framework. When effectively adopted, it becomes more than just a cyclical process; it evolves into a foundational element for strategic success. This strategic integration illustrates that, irrespective of industry, businesses can effectuate substantial gains through methodical quality enhancements and systematic management approaches.

Overcoming Challenges in Implementation

Tackling Initial Resistance

Implementing the Shewhart Cycle into an organization’s strategic planning process can sometimes lead to initial resistance. The cycle, with its roots in the PDCA (Plan-Do-Check-Act) methodology, challenges traditional methods with its emphasis on continuous improvement and quality management. A common hurdle is overcoming the reluctance to change established processes. This fear can be mitigated by fostering a culture that celebrates incremental improvement and learning. Management should stress the importance of each phase, emphasizing that every step, no matter how small, contributes to the larger goal of enhancing quality and efficiency.Managing Transition into Continuous Improvement

To smoothly transition into a continuous improvement mindset, organizations need to focus on effective communication. Clearly articulate the benefits of the Shewhart Cycle to all stakeholders. Highlight how the cycle aligns with the organization's mission by improving quality control and maintenance. By doing so, you build a solid case for the shift towards continuous improvement. Encouraging teams to look at change as a series of small-scale projects, rather than a wholesale upheaval, facilitates a smoother progression.Navigating Resource Allocation

Resource allocation presents another challenge in implementing the Shewhart Cycle. Ensuring that there are sufficient training and project management resources to support new processes is crucial. This often means re-evaluating current resource distribution and possibly reallocating to better support cycle pdca initiatives. Maintaining a balance between immediate operational demands and long-term strategic improvements requires careful planning and prioritization.Creating a Supportive Environment

Finally, for the PDCA cycle to thrive, creating a supportive environment that encourages experimentation and problem solving is vital. Encourage teams to embrace failure as a part of the learning process, much like the principles found within the Deming cycle. Fostering an atmosphere where feedback is welcomed and utilized in the check phase of the Shewhart cycle amplifies both individual and organizational growth. Continuous improvement is not just a process, but a shared commitment. Implementing the Shewhart Cycle is not without its challenges, yet overcoming these obstacles can significantly enhance the quality and effectiveness of strategic planning. By focusing on cultural, communicative, and operational adjustments, organizations can fully realize the benefits of this dynamic approach.Future-Proofing Your Strategy

Ensuring Long-lasting Strategic Impact

Operating amidst constant change and uncertainty means that businesses must focus on embedding long-term resilience within their strategy. Here’s how the principles of the Shewhart Cycle can ensure your strategy remains robust and adaptable:

- Continuous Learning and Adaptation: The cycle of planning, doing, checking, and acting fosters a culture of ongoing learning and adaptability. Regular assessments following each phase of the cycle encourage teams to identify areas for improvement and incorporate necessary adjustments quickly.

- Dynamic Process Management: Implementing the PDCA methodology in your organizational framework aids in dynamic process management by establishing a routine for constant quality management. This repetitive stepping through Shewhart's cycle ensures that strategies remain relevant and effective.

- Quality Control and Maintenance: By integrating checks and balances through the PDCA method, companies can sustain high quality control standards over time. This involves meticulous plan check metrics aimed at preserving and enhancing process efficiency.

- Incremental Improvement: Balancing large-scale goals with small scale change initiatives allows for maintaining momentum while avoiding burnout. This incremental approach, inspired by Walter Shewhart, champions progress without upheaval.

- Embedding Continuous Improvement Culture: Encourage an organizational mindset of continuous improvement where employees actively partake in identifying potential step modifications within the project. This collaborative endeavor underlines the essence of the Deming Cycle methodology.

Embracing these concepts ensures your strategic game plan does not just withstand attacks over time but emerges more fortified at every turn. As you continue deploying the PDCA cycle within your company's strategic framework, think about how each project can be fine-tuned for perpetual superiority, just as you would for achieving operational excellence via Lean Six Sigma.